A flight over the road with your Rolex GMT-Master

In 1954 Rolex introduced the GMT-Master ref. 6542. This watch had been developed together with Pan Am Airlines so that their pilots could fix a second time zone on their watch (GMT means Greenwich Mean Time).

A short product description of the ref. 6542:

Ref. 6542 aka Pussy Galore

Production Period: 1954-1959

Model Name: Rolex GMT Master

Caliber: 1036 (1954-1959), 1065 (1957-1959), 1066 (1957-1959)

Pressure proof to 50m/165ft

This was the first GMT Master.

It was launched 1954. It was developed on the basis of a regular Turn-O-Graph (Ref. 6202). The modifications were a different bezel and a modified movement.

The first version of the Ref. 6542 had a bakelite bezel insert. As this bezel was likely to crack, it got replaced by a metal bezel in 1956.

The bakelite bezel was luminous.

The name Pussy Galore originates from a character in a James Bond movie, wearing this watch.

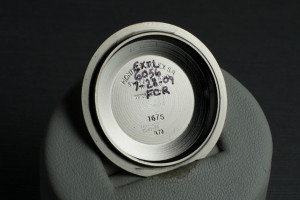

In 1959 ref. 6542 was replaced by the GMT-Master ref. 1675 which stayed in production until 1980.

A short product description of the ref. 1675:

Production Period: 1959-1980

Model Name: Rolex GMT Master

Caliber:

1565 (1959-1964) 18000A/h

1575 (1965-1980) 19600A/h (hacking introduced 1971)

Pressure proof to 50m/165ft

Bracelet: Oyster 78360, Jubilé 62510

Glass: Acrylic crystal

Indexes: Tritium

Crown guards introduced, pointed crown guards until 1964/65 (with chapter ring dial)..

New inprint on dial: “Superlative Chronometer Officially Certified”.

Until late 60s: Small GMT-hand, afterwards large GMT-hand.

Early 1970s: All black version introduced.

The hands are in the following order: GMT/Hour/Minute/Second see this picture.

1959-1964:

Caliber 1565

Gloss dial

Thin case

1965-1980

Caliber 1575

Matt dial with white printing.

Other Variants:

Ref. 1675/8 Gold (Leather or Oysterbracelet 7208/8, Jubilébracelet 6311/8).

Ref. 1675/3 Steel/Gold (Oysterbracelet 78363, Jubilébracelet 62523), 14k gold.

Both variants: Early versions with golden crown on dial, late versions just with imprinted crown.

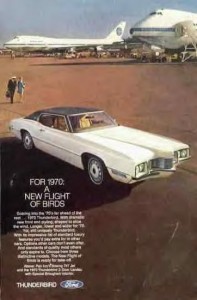

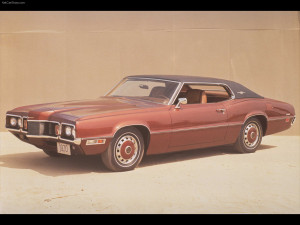

In the spring of 1968 Henry Ford II made Semon E. ‘Bunkie’ Knudsen CEO of the Ford Motor Company. Although Knudsen was not a designer, he interfered big time with the development of the new Ford Thunderbird that had to be for sale in 1970.

Knudsen wanted the new Thunderbird to be built on a mid-size chassis (he knew Pontiac was going to do the same with their ill-selling Grand Prix) and not on the current full-size chassis. He also tried to get the for him characterising ‘bold nose front ends’ (the designers called these ‘Bunkie Beaks’) and ‘massive rear quarters on the car.

Although ‘Bunkie’ was fired by Ford in september 1969 after a big clash with Lee Iacocca he had firmly left his autograph on the new Thunderbird. They kept the full-size chassis but his ideas about the front and back of the car had made it to production.

After a long and exhausting intercontinental flight the 1970 Ford Thunderbird was the ideal car for a Pan Am pilot to drive home and only having to read one time zone on his Rolex GMT-Master.

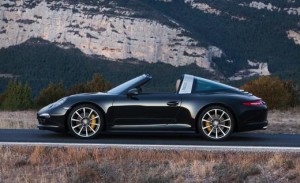

In 2014 I would like to couple the same Rolex model, now called GMT-Master II (ref. 116719BLRO), to a totally different car than the Thunderbird (which officially doesn’t exist anymore).

For many years a familiar sight on the Dutch highways.

For more than 35 years Dutch police have been driving in the Porsche. In 1960 the first Porsche, type 365 B, was the delivered to the ‘Sectie Bijzondere Verkeerstaken’. The real start of the SBV was January 1st 1962. They had 12 Porsches 365 B. Until the end of 1995 the police have been using Porsches, in total more than 500. In the picture the Pon brothers delivering the first Porsche 365 to the police.

In 2014 Porsche has made a perfect modern interpretation of the 911 Targa from 1965. After the start of the production of the 911 fifty years ago 13% of the cars sold is a Targa. Technical highlight is the electro-hydraulic roof construction which can fold the roof and rear window in 19 seconds.

When the Rolex GMT-Master was introduced in 1955 it had a bezel made of Plexiglas which underside was painted red and blue. Plexiglas was very vulnerable to damages and discolouring by UV light. In 1959 the bezel was replaced by one made of anodised aluminium.

In 2005 Rolex had developed a bezel made of ceramic material, called Cerachrom. Ceramic is a material that is extremely robust and durable: practically scratch resistant, resistant to corrosion and it’s colours are insensible to ultraviolet radiation. Ceramic is high-gloss and offers a razor sharp contrast with the engraved and with a thin layer of gold or platinum covered numbers and signs on it’s surface.

The manufacturing process of the Cerachrom bezel starts with the ceramic which now has a green colour.

One of the biggest challenges for Rolex in the development of a ‘Pepsi’ bezel for the 2014 GMT-Master II was making the colour red. In general colours are made by adding natural minerals that can withstand the extreme high temperatures in the fabrication process of ceramic. Red is a colour for which there are no stabile mineral pigments to manufacture Cerachrom.

The following is what Rolex tells us about their solutions for the problems there were in the development of the ‘Pepsi’ bezel:

Red and blue Cerachrom

The name “Cerachrom” derives from a contraction of the word “ceramic” juxtaposed with the suffix “chrom” from the ancient Greek word for “colour”. The range of available shades for ceramic is however restricted by its very manufacturing process. Colours are generally created by adding mineral pigments that can withstand the very high temperatures at which the ceramic is fired for its densification and to acquire its characteristic hardness. Red, typically, is a colour for which no stable mineral pigments exist to create a Cerachrom component. Rolex nevertheless managed, in the first instance, to produce a red ceramic according to a secret process. But this innovation represented only half the journey – or, more precisely, took the brand only half way to manufacturing the emblematic red and blue Cerachrom insert.

Rolex’s in-house engineers finally found an answer to the second half of the challenge. The ingenious process consists of introducing an intermediate step in the manufacture of the standard Cerachrom insert. During this innovative bulk-colouring step, half of the red ceramic insert is coloured blue. The colour is achieved by impregnating the part of the insert representing night-time hours, between 6 p.m. and 6 a.m., with a controlled quantity of a solution of chemical compounds. The solution is added before sintering at more than 1,600 °C, when the ceramic acquires its mechanical resistance properties as well as its colour. In the course of this firing, the ceramic densifies and the added compounds react with the basic elements of the red Cerachrom insert to conjure up the final blue colour.

Although the idea in itself may appear simple, a number of major technical hurdles had to be overcome before it could be implemented: the formulation of a solution of precursor chemical compounds that would turn red into blue; the homogenous application of an appropriate quantity of this solution; ensuring a sharp, precise and clear demarcation between the two coloured areas, the definition of the precise length of time and temperature for the sintering so as to prevent any distortion of the piece. Every single one of these parameters is crucial for the success of the process and the quality of the final product.

Seeing the 2014 Rolex GMT-Master II with the ‘Pepsi’ bezel out of the corner of your eye makes blasting in the new Porsche 911 Targa just that little bit more comfortable.

Jaap Bakker